The Medical Technology Manufacturing industry is a highly regulated sector that must adhere to strict quality control standards, such as FDA regulations. However, manufacturers face numerous challenges that can impede their ability to maintain these standards. Manual processes, paperwork, siloed data, and a lack of modern software can lead to inefficiencies, errors, and compliance issues.

Kypeco MES is a comprehensive software solution that addresses these challenges and optimizes Medical Technology Manufacturing processes. With Kypeco MES, manufacturers can improve OEE, reduce downtime, and streamline quality control processes. The software enables manufacturers to use advanced technologies like ML and AI to monitor and improve processes, digitalize manufacturing processes, and attract a younger workforce. Kypeco MES is a vital tool in advancing Medical Technology Manufacturing and enabling the industry to embrace digital transformation and Industry 4.0 concepts. The software enables manufacturers to gain end-to-end visibility and control over their supply chain, optimize resources, and achieve greater agility while maintaining strict quality control standards. Ultimately, Kypeco MES is a key step in progressing toward Smart Industry Readiness and driving innovation in the Medical Technology Manufacturing industry.

Transform your operations with the modern MES smart apps, shifting away from traditional paper-based and whiteboard systems to boost efficiency and optimized processes with our digital platform.

Embrace a future-ready digital manufacturing landscape by leveraging advanced MES technologies, to drive innovation.

Integrate MES cloud computing and industrial technology to unlock new possibilities, enhance scalability.

With our MES, Identify inefficiencies and maximize productivity, ultimately re-evaluate production processes.

Leverage the power of digital data analytics to make informed decisions, optimize resource allocation, and drive continuous.

With the help of our MES, achieve maximum efficiency by optimizing performance, availability, and quality across your operations, resulting in improved productivity and enhanced competitiveness.

Implement advanced MES monitoring techniques to achieve better control and visibility over your production lines.

In the MES platform, monitor key performance indicators, and make data-driven decisions for optimized production lines.

Optimize production flow and synchronization with our digital MES shopfloor production pacing board.

Identify and address production failures swiftly with the MES failure reasons dashboard.

Attract and engage the younger workforce by adopting next-generation manufacturing execution system technologies. Say goodbye to paperwork frustrations and embrace a digital manufacturing workplace.

Transition to a paperless digital future and align with the needs of the younger workforce, update operations and boost productivity with modern MES.

Develop modern MES tech solutions tailored to younger workers. Empower them in eliminating paperwork frustrations.

Anticipate the future of manufacturing with a forward-looking outlook. Embrace modern MES technology advancements for a competitive edge.

Mobile accessibility for a younger workforce. empowering them to eliminate frustrations caused by paperwork with our MES.

Optimize asset management with a private assistant providing MTBF, MTTR, and MTTF insights. Streamline maintenance and enhance operational efficiency with our digital MES platform.

With the MES, optimize asset performance and enhance management strategies with comprehensive metrics that provide valuable visibility.

Measure downtime frequency with Mean Time Between Failures to enhance maintenance planning and minimize disruptions.

Reduce equipment downtime with advanced metrics, enabling swift resolution of issues and optimized operational efficiency.

Utilize Mean Time to Failure to optimize asset lifespan, reduce unplanned failures, and maximize operational efficiency.

Optimize work order management with a powerful smart scheduler, leveraging machine learning and AI for efficient task allocation and resource optimization in your medical equipment industry.

Provides valuable insights into the performance of equipment, enabling proactive data-driven work order scheduling.

Work order visualization for optimal tracking and resource planning, ensuring optimized operations with our digital platform.

Effortlessly schedule work orders with our digital transformation and data-driven insights, ensuring optimal task sequencing.

Achieve seamless connectivity between work order management, ERP, and e-commerce digital platforms with MES.

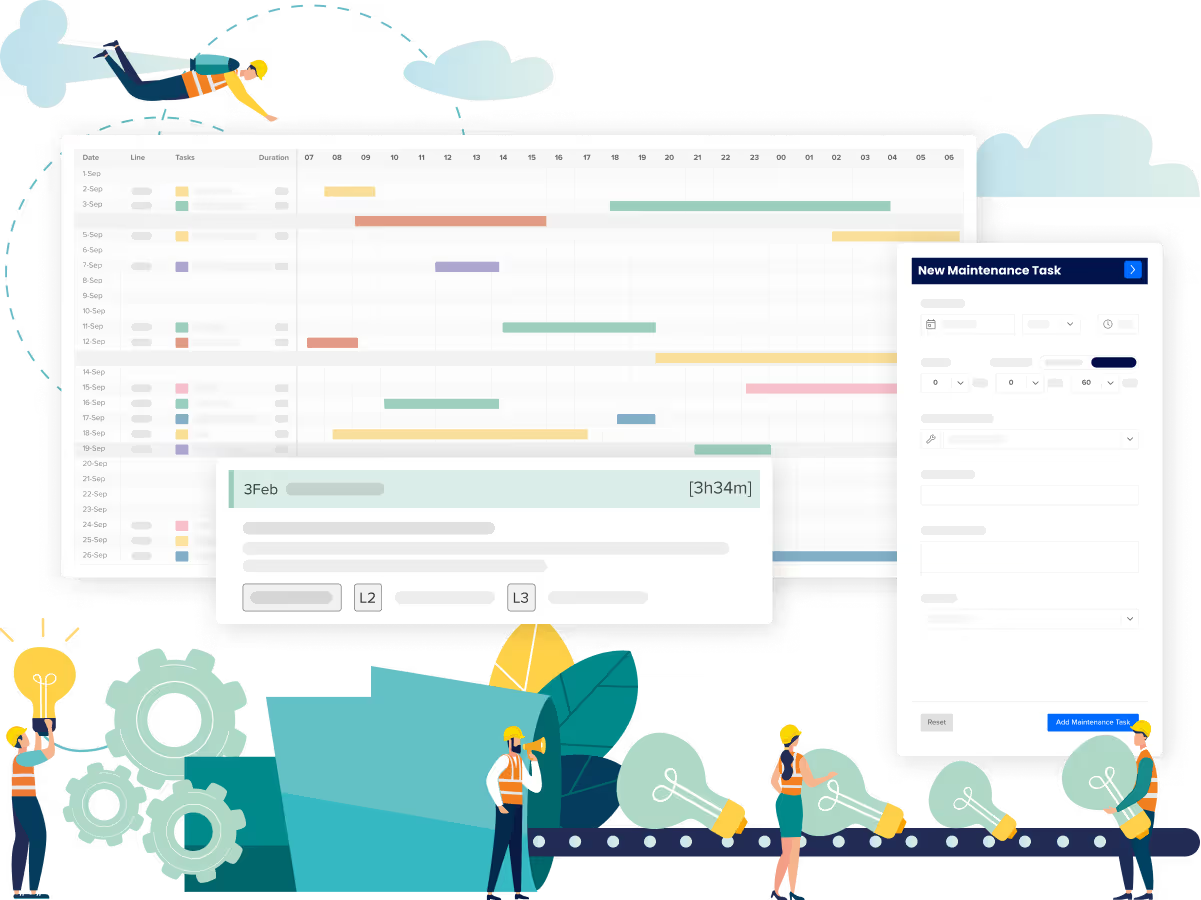

Simplify maintenance tasks with an intuitive system, allowing you to effortlessly plan and schedule operations for seamless workflow management with the help of our modern manufacturing execution system.

Visualize your maintenance planning with clarity and ease, empowering you to efficiently allocate resources and optimize workflow management.

Maximize work order efficiency enabling smooth scheduling and improve uptime with our Gantt & Calendar view MES.

Recurring task scheduling and simplify maintenance planning with our digital MES platform.

Simplify SOPs for breakdown maintenance, ensuring swift response with the MES.

Experience the power of automated and real-time reports, eliminating delays and ensuring timely access to critical insights for enhanced decision-making with the help of our modern MES platform.

With the help of our digital MES, embrace a paperless future, leveraging automated and real-time reports to upgrade operations and drive efficiency.

Digital automated reporting enables data-driven process optimization, empowering manufacturing operations teams.

Embrace digital business transformation with paperless solutions, empowering leaders to drive innovation and growth.

Enable financial executives to make informed decisions with data-driven insights from advanced reporting capabilities.

Drive cross-functional collaboration by providing teams with access to transparent and centralized data, promoting efficient communication and informed decision-making with our modern MES platform.

Bid farewell to siloed data and embrace a unified approach, enabling seamless access and collaboration across your organization.

Enhance collaboration through digital tools that enable real-time communication and information sharing with our MES.

Embrace inclusivity with a solution that breaks down data barriers, ensuring access and collaboration for all.

Establish a continuous feedback loop to drive improvement and innovation across teams and projects with our MES.

Harness the power of your manufacturing data to unlock valuable insights, enabling informed decisions and driving operational excellence with advanced digital manufacturing transformation.

Make informed manufacturing decisions with actionable insights derived from comprehensive data analysis with our digital platform.

Identify root causes of manufacturing issues with data-driven analysis, enabling targeted problem-solving.

Analyze production trends to uncover valuable insights for strategic decision-making and performance optimization.

In modern MES, optimize costs and minimize loss through efficient resource utilization and waste reduction,

Leverage a white-label MES platform customized to your exact needs, with your branding, locale, and workflows for seamless operations with modern digital MES platform in your medical technology manufacturing.

Tailor the MES platform to fit your manufacturing processes, ensuring it aligns with your unique workflows for optimized operations.

Evaluate production KPIs and OEE to monitor performance and implement targeted improvements with our digital MES.

Brand the Kypeco platform to reflect your identity and create a consistent user experience.

Customize SKUs, failures, and assets to align with your specific product portfolio and operational requirements.

120+

Real-time integration ensures accurate and synchronized data visibility, eliminating delays and discrepancies, and helps solve the lack of real-time data visibility challenges.

Continuous monitoring detects and resolves inconsistencies and inaccuracies, ensuring data integrity.

Kypeco ensures real-time data synchronization across systems, enabling up-to-date and consistent data access, and helping solve siloed data.

Kypeco monitors data movements and tracks data flows to ensure traceability across systems, helping solve the lack of data traceability.

Kypeco utilizes advanced analytics for accurate demand forecasting, enabling efficient production planning and resource utilization.

Dynamic production planning, allowing rapid adjustments to align with changing demand scenarios, helps solve the inability to respond quickly to changes in demand.

Kypeco's process automation capabilities streamline production processes, enabling organizations to optimize production quickly and efficiently.

Data visualization tools provide a clear and concise view of processes, enabling quick insights into bottlenecks and inefficiencies.

Kypeco's predictive maintenance features enable organizations to schedule maintenance proactively, reducing downtime and improving efficiency.

Root cause analysis is to identify underlying factors contributing to identifying bottlenecks and implementing targeted solutions.

Kypeco's lean manufacturing approach helps organizations identify and eliminate waste and scrap through process optimization and waste reduction.

Kypeco's profitability analysis features enable organizations to analyze production costs and revenues, identifying opportunities for profit maximization.

Our business intelligence capabilities enable organizations to generate insights on customers, competitors, and industry trends, enhancing competitiveness.

Kypeco enables organizations to manage talent effectively, attracting, developing and retaining skilled employees.

Organizations can manage employee performance effectively, providing employees with feedback and opportunities for improvement, and enhancing experienced workforce retention.

Kypeco's employee engagement features enable organizations to engage and retain top talent, addressing bottlenecks and enhancing process efficiency.

Kypeco's shared project management capabilities enable organizations to manage projects collaboratively across department.

Our MES enables us to automate and optimize quality control processes which helps reduce high manual labor costs.

Track production costs accurately, identify areas for cost optimization, and enhance process efficiency with our MES.

Kypeco's real-time data features enable organizations to access and analyze data in real time, enhancing decision-making speed.

Solution for Shopfloor Workforce

Top Values for Managers

Strategic Solution for Executives

Read more about how various teams in your manufacturing can be benefited by adopting a modern Manufacturing Execution System (MES)

See all digital manufacturing prospects for your entire workforce.

Our tailored solutions for the medical technology industry digitalize your processes and increase efficiency, providing you with a competitive edge.

Contact us to learn how we can benefit your medical technology manufacturing operations.