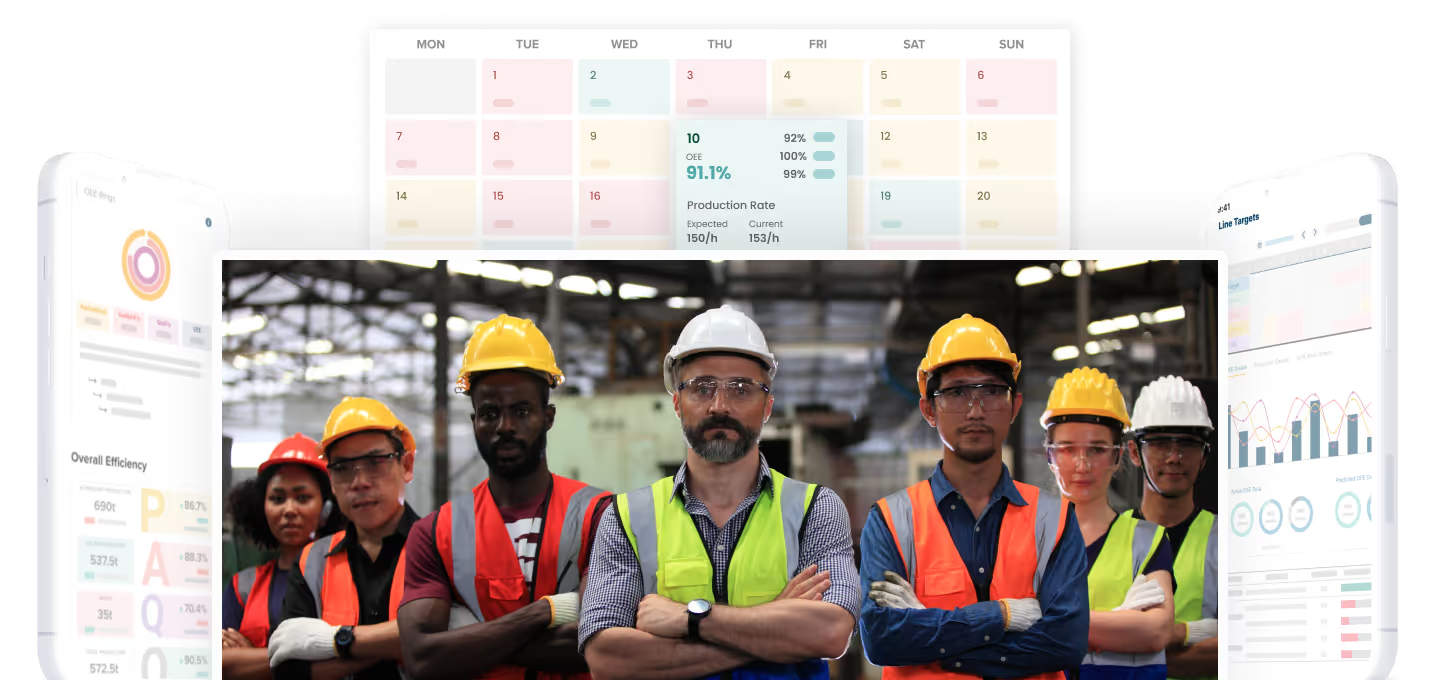

Future-proof your manufacturing operations with our MES platform and empower your management team with real-time data insights, seamless collaboration, and streamlined workflows.

Take the lead in revolutionizing manufacturing processes by enabling simplified processes and streamlined operations.

Effortlessly manage and streamline production processes with modern MES.

Get up-to-the-minute updates and data analysis for informed decision-making.

Access all relevant data and insights in a single system to eliminate siloed data.

Enhanced communication and coordination among team members for better productivity.

Stay in the know with real-time reporting and insights.

Ready to revolutionize the manufacturing process? Kypeco offers an array of powerful features to help you take your production to the next level. With tools for assets management, workflow automation, and more, you can streamline your operations and optimize your output. Explore a digital solution today!

Optimize equipment performance with real-time OEE monitoring system, providing detailed insights into your production output.

Plan your production schedule efficiently, make informed decisions, and identify opportunities for improvement.

Optimize the production schedule by automatically scheduling work orders based on priority and resource availability.

Minimize downtime and keep equipment running smoothly with maintenance planners, helping you schedule maintenance with ease.

Analyze historical data and identify trends in the manufacturing process to predict future outcomes, optimize workflow.

Stay updated with the root causes of failures, minimize disruptions, reduce costs, and improve the reliability of the manufacturing.

How does Modern software help managers in manufacturing?

Improve the production and operational processes with simple manufacturing workflow software. Kypeco provides the real-time tracking of production status, and makes communication a breeze. It equips you with Production Management Platform, so you can make smart, data-driven decisions.

Optimize productivity and product quality by assigning jobs to the most suitable production lines.

Optimize production capacity by analyzing the real-time production feedback of each line and material to plan jobs accordingly.

Monitor manufacturing productivity with real-time manufacturing insights from Line Dashboards.

Access real-time data for all manufacturing sites remotely with visual factory monitoring. Eliminate the need for emails or phone calls.

Centralize and optimize your manufacturing operations with a dashboard that displays real-time data from all production lines across the site, helping you to increase efficiency.

Monitor all production machines across the site with a centralized dashboard to identify overarching issues and find solutions for the worst-performing lines.

Easily import work orders from your ERP system or create them directly in Kypeco.

Improve the Mean Time Between Failures (MTBF) and Mean Time Between Repairs (MTBR) by analyzing real-time production insights.

Schedule and automate recurring maintenance for assets and analyze their failure rates for each production line, the entire site, or each SKU variant to improve overall equipment effectiveness (OEE) and reduce downtime.

Analyze the impact of planned and unplanned downtimes on production lines to optimize productivity.

Get actionable insights through machine learning (ML) and understand patterns to reduce downtime.

Create and assign maintenance tasks, and keep the entire team informed about the progress and completion to ensure all necessary steps are followed.

Track the real-time performance of all production machines with Overall Equipment Effectiveness (OEE) dashboards, providing insights into availability, performance, and quality metrics.

Identify the main reasons for manufacturing performance failures attributed to the workforce and shopfloor operators.

Track critical failure reasons for production lines, machines, and equipment to prevent downtime and boost productivity on the shop floor.

Analyze quality failures for each production line or SKU to identify the best and worst performers for specific tasks and minimize waste.

The calendar-style monthly production board is a favorite among managers, as it visualizes day-by-day production KPIs, without every needing to generate the reports again.

Make informed decisions with real-time production rate tracking for each line and improve manufacturing efficiency.

Get actionable insights through Machine Learning (ML) and Artificial Intelligence (AI) algorithms to understand the overall manufacturing performance and identify shortcomings.

Analyze failure rate, production rate, and hourly trends throughout the day to identify areas for improvement and optimize production.

Improve product quality with SKU-specific failure analysis. Intelligent shopfloor reports to identify issues and implement improvements.

Optimize manufacturing with monthly automated insights. Analyze performance, identify trends, make data-driven decisions for process optimization.

Automate report generation for higher leadership. Collect data once and generate all reports automatically to avoid siloed data.

Get yearly reports generated for you as a professional printing press does them. No need to spend time compiling data - we've got you covered!

All benefits for Manufacturing Management

18

Data Aggregation Levels

12+

Processes Reduced

1min

Data

Granularity

Yes

Create

Unlimited Reports

15+

Roles

Supported

<15m

Configuration

Time

Teams in manufacturing can take data-driven decisions and execute better with Kypeco.

See all digital manufacturing prospects for your entire workforce

12+ Planners

Never waste time creating reports manually

Spend more time in taking smarter data-driven decisions.

Managers often struggle to effectively stay on top of their team's performance and analyze the production process without digital solutions, which can result in difficulties in decision-making, coordination, and resource allocation.

Identifying bottlenecks to track progress, coordinating work to managing resources; making it difficult for managers to make informed decisions and take corrective action.

Identify bottlenecks, track progress, and make informed decisions.

Coordinate work and manage resources, set accountability and motivate the workforce.

Real-time insights into the underlying causes to take smart decisions, faster.

Kypeco provides managers with a comprehensive overview of their manufacturing operations, enabling them to monitor production processes, maintain quality control, manage inventory levels, and have more time for production tasks, all while enjoying a cup of coffee.

Critical data insights such as failure reasons, trends, equipment utilization, loss and cost analysis, and annual performance. Identify patterns in operations and optimize resources for better improvement.

Transparent data allows to identify bottlenecks, track progress, and make informed decisions.

Improve communication by reducing the likelihood of miscommunication and errors.

Make informed decisions and take corrective action when needed with Key Metrics.

4 Platforms

84+

Shift Insights

108+

Daily Insights

144+

Weekly Insights

160+

Monthly Insights

200+

Yearly Insights

Solution for Shopfloor Workforce

Top Values for Managers

Strategic Solution for Executives

Read more about how various teams in your manufacturing can be benefited by adopting a modern Manufacturing Execution System (MES)

See all digital manufacturing prospects for your entire workforce.

Our smart manufacturing solution is designed to optimize your production process, reduce downtime, and increase efficiency. Say goodbye to manual processes and hello to smarter manufacturing.

Contact us to learn how it can benefit your manufacturing operations.