Self-Configure Your MES for Your Production Processes

With advanced factory software's MES solution, you have the power to customize the platform to fit your unique production processes. From branding options to intuitive training,our digital MES ensures that your factory's needs and style are always in focus. Say goodbye to rigid systems and embrace the freedom to configure your MES according to your requirements.

A Plug-n-Play Solution to Fit Your Processes

IfElseCloud offers an MES platform that is so intuitive, your workforce can start using it without any training. The platform seamlessly connects with over 50 external platforms, including ERP and CRM systems, with just a few clicks. This plug-n-play capability ensures that the MES adapts effortlessly to your manufacturing processes.

- Minimal Training

The modern user experience of our smart MES solution is designed for modern teams, minimizing the need for extensive training. Your workforce can quickly adapt to the platform, reducing downtime and maximizing productivity. - Fully Configurable

Advanced MES allows for complete customization to adapt to your unique processes. Whether it's workflows, data fields, or user roles, the platform can be tailored to your specific requirements, ensuring maximum impact on your operations. - MES Your Way

With our smart factory software, you have the freedom to configure the MES according to your preferences. The platform is fully customizable, allowing you to create an MES that aligns perfectly with your factory's needs and style. - Brand Your MES

Make your MES a reflection of your brand by customizing it with your logo, color scheme, and other branding elements. This customization option not only enhances brand recognition but also creates a cohesive and familiar environment for your teams.

Streamlining Complexity: Empower Your Manufacturing Operations with Automated Workflows for Enhanced Efficiency.

Create and Automate Complex Production Workflows

Our digital factory software provides a powerful SaaS platform for manufacturers to configure and automate complex production workflows. With features like brand recognition, secured access, flexible data display, ERP metadata mapping, stunning reports, and seamless data import, Our digital factory software empowers you to streamline your production processes and optimize efficiency.

Brand Recognition

Our digital software allows you to customize your MES platform with your brand's domain, logo, color scheme, and theme. This branding feature ensures that the MES reflects your brand identity and creates a consistent user experience for your teams.

Secured Access and Data Security

With Our digital production software, you can connect your MES platform with your existing Active Directory (AD) for Single Sign-On access. This integration reduces login issues and enhances data security by granting access only to authorized users. Additionally, the access control feature provides granular control over user access, ensuring data security and compliance with industry standards.

Flexible Data Display

Our digital manufacturing software allows you to configure videowalls for meeting rooms, enhancing data visualization and enabling better decision-making, visibility, and collaboration. By customizing the data display, you can present critical information in a visually engaging manner, promoting effective communication and alignment among teams.

ERP Metadata Mapping

Seamlessly integrate your MES platform with your ERP system by customizing ERP properties and mapping them to the MES. This customization ensures that the MES aligns with your specific manufacturing needs, improving efficiency and productivity by facilitating seamless data exchange and synchronization.

Use Stunning Reports

IfElseCloud's MES solution provides pre-built reports that can be customized to showcase your manufacturing data in a visually appealing format. These reports allow you to put the color and brand of your manufacturing on display, engaging your teams and impressing stakeholders with meaningful insights.

Import SKUs & Jobs

Streamline your data entry process and improve accuracy by importing SKUs and work orders directly into the platform. This feature eliminates manual data entry, saving time and reducing the risk of errors, while providing real-time visibility into your production processes.

Import Failure Reasons

Quickly identify and address production issues by importing failure reasons for each line or site. By gaining valuable insights into the causes of failures, you can take proactive measures to optimize your processes and improve overall efficiency.

Production Multiplication

Improve production efficiency and optimize output by importing the production multiplication factor of each line. This feature allows you to set realistic production targets and track performance against those targets, facilitating continuous improvement and increased productivity.

These features empower you to self-configure your MES platform according to your specific production processes, ensuring maximum efficiency and operational excellence.

Agile Manufacturing Software Solution for Industry 4.0

Scheduling Software for Manufacturing

Unified Digital Manufacturing Hub for Modern Industry Teams

Shoplfoor Intelligence for Modern Production Practices

Use Configuration Templates

Our smart factory software offers over 300 configurable properties, allowing you to make the platform your own. With a design that keeps your manufacturing processes in mind, Our smart factory software provides configuration templates that enable you to quickly set up and customize your MES according to your specific needs.

Make it Work with Your Process

Our Digital factory software allows you to configure the smart factory software to seamlessly fit your manufacturing processes. From work orders to shop floor production failure reasons, you can easily adapt the platform to align with your unique operational workflows. This level of customization ensures that Our smart factory software becomes an integral part of your production process, improving efficiency and driving productivity.

Make it Work with Your Teams

With smart MES, you have the ability to configure the platform to match the language and terminologies used by your teams. By customizing internal key terms and allowing for comments and notes on failures, you can enhance collaboration and communication, enabling smooth interaction between team members and the MES platform.

Make it Work for You

Our digital factory software allows you to configure the platform to deliver the reports and insights you need, precisely when you need them. By tailoring the system to your specific reporting requirements, you can access real-time data, analyze trends, and gain valuable insights that drive informed decision-making. This level of customization empowers you to become more productive, optimize your manufacturing processes, and achieve operational excellence.

Driving Collaboration and Efficiency: Implementing a Business-Wide MES Configuration for Integrated Operations.

A Business Wide MES Configuration

With smart MES solution, you can configure the platform to meet your business needs across multiple levels, including site, line, and user roles. This granular configuration capability ensures that you can tailor our advance factory software to specific locations, production lines, and user access, optimizing data, insights, and access for each segment of your organization.

- Set Site-wide Standards

Configure our advance factory software for each site or multiple sites, tailoring data, insights, and access to specific locations. This enables you to maintain site-wide standards while accommodating variations in processes and requirements. - Configure Each Production Line

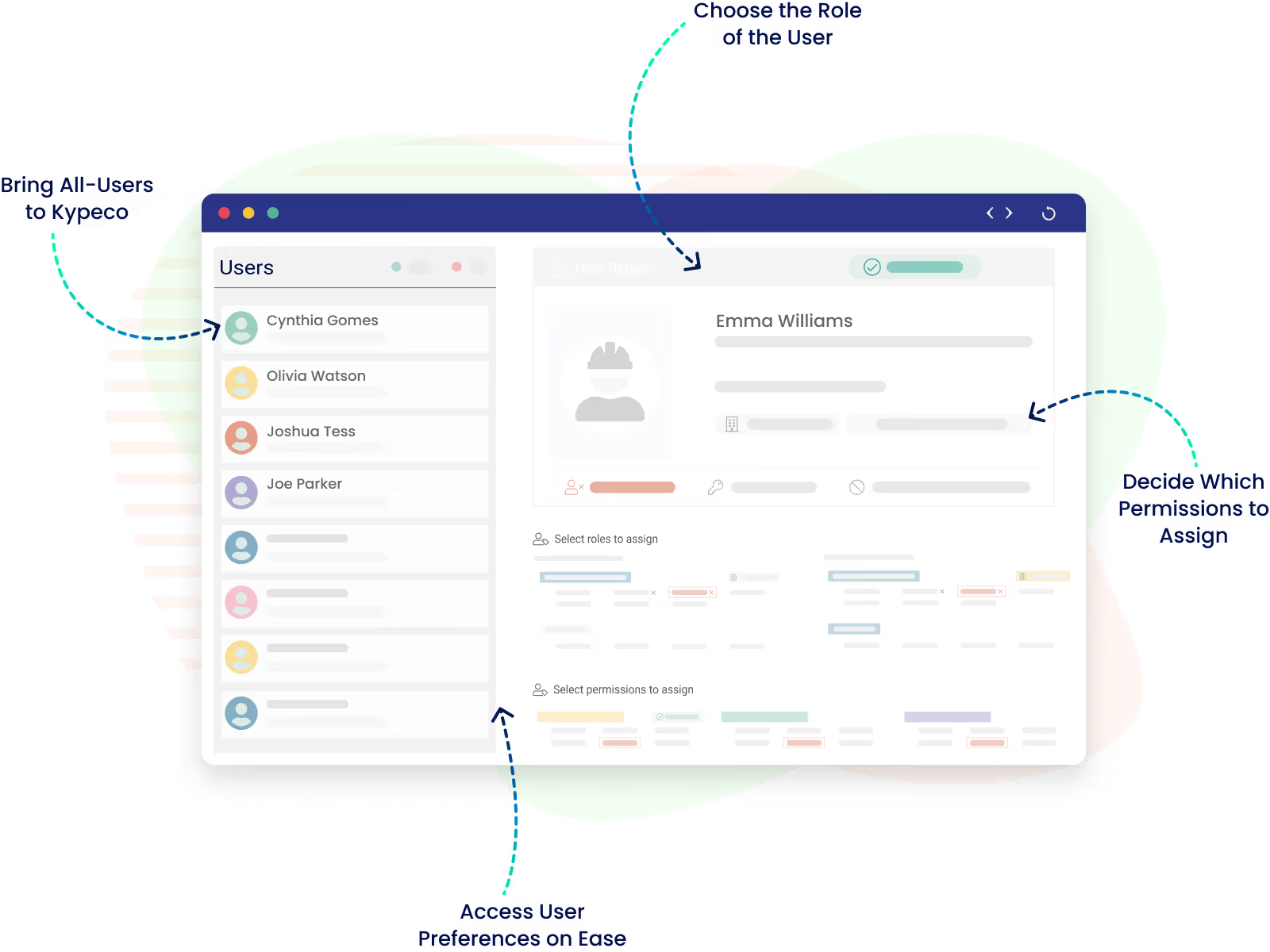

Further customize our smart factory software with line-specific configurations to gain greater control and granularity over your data. This allows you to optimize performance, monitor specific production lines, and drive operational efficiency. - Connect All Domain Users

Connect all domain users to the platform, promoting wider collaboration and knowledge sharing. By configuring our smart factory software to meet the specific needs and requirements of different user roles, you can enhance communication and efficiency across your organization. - Centralized Access Control

Maintain complete control over data access and editing permissions by configuring user role-based access control. This centralized access control ensures data security, compliance, and streamlined operations.

Tailor Your MES to Perfection: Configure it to Fit Your Shop Floor's Unique Needs and Processes.

Configure Your MES - The Way You Like It

Our smart factory software offers a white-labeled platform that provides full customization and branding options. This allows you to create an MES platform that truly represents your manufacturing operations, enhances your brand identity, and aligns with your specific requirements. With features such as language localization, production KPIs and OEE benchmarks, failure reasons, work-order SKU definitions, and asset management, you can configure your MES to optimize your production processes and drive efficiency.

Production KPIs & OEE Benchmarks

Revolutionize production by customizing key performance indicators (KPIs) and overall equipment effectiveness (OEE) benchmarks. Define and prioritize critical issues, optimize resources, and achieve better results by setting tailored KPIs and OEE targets that align with your manufacturing objectives.

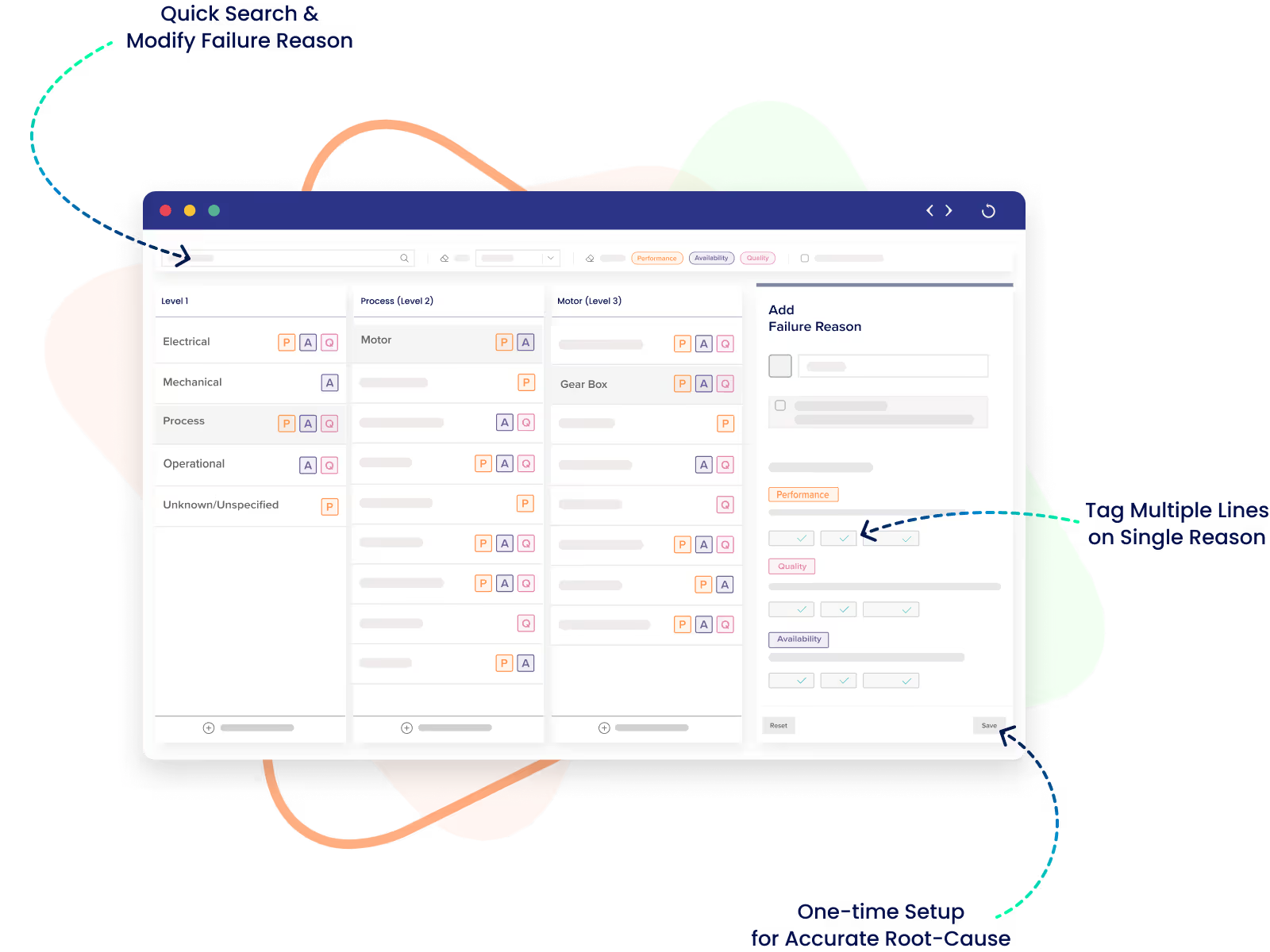

PAQO Failure Reasons

Set up failure reasons applicable to your specific manufacturing processes. By defining failure reasons and periodically updating them, you can streamline your production processes, identify areas for improvement, and implement corrective measures to minimize downtime and enhance efficiency.

Work-Order SKU

Define SKU definitions with their associated production rate and cost. Once defined, you can easily set up work orders with a single tap, providing real-time visibility into your production progress, resource utilization, and overall performance. This feature simplifies data entry and improves accuracy, enabling better decision-making and resource allocation.

Assets and Equipment

Import and manage all the equipment used in your production processes. Define equipment attributes, estimated time for repair and replacement, and maintenance schedules. By effectively managing your assets, you can ensure their longevity, reduce unplanned downtime, and optimize maintenance activities.

Set Production Targets

Whether you engage in discrete, batch, or continuous manufacturing, Our smart factory software allows you to set production targets to optimize your production processes. By defining hourly production targets, you can align resources, monitor performance, and drive efficiency, leading to increased productivity and improved operational outcomes.

Rapid Setup and Integration in Just a Few Hours. Ready?

Our smart factory's MES solution, empowers manufacturers to self-configure their MES according to their unique production processes. With a plug-n-play platform, intuitive training, and a wide range of customization options, you can optimize your operations, streamline workflows, and drive efficiency. Whether it's configuring the platform to fit your processes, aligning it with your teams, or tailoring it to meet your business needs, our smart factory software provides the flexibility and functionality required to achieve operational excellence.

Experience the power of self-configuration with IfElseCloud's MES solution, and unlock the full potential of your manufacturing operations. Contact IfElseCloud today to learn more about how our smart factory software can revolutionize your MES configuration and drive sustainable success in your factory.