Digital Manufacturing software for Manufacturing Managers

Manufacturing managers are at the forefront of driving success in the manufacturing industry. Their ability to simplify production workflows, access real-time data insights, and enhance collaboration is crucial for staying ahead of the competition. With the right digital manufacturing software, managers can unlock a new level of efficiency, productivity, and quality in their operations. Let's explore how our MES platform can empower manufacturing managers to elevate their processes and drive exceptional results.

1. Simplified Production Workflows

- Effortlessly manage and streamline production processes with a modern MES.

- Eliminate complexities and inefficiencies that hinder productivity and performance.

- Embrace a user-friendly interface that simplifies tasks and boosts efficiency.

2. Real-time Data Driven Insights

- Gain up-to-the-minute updates and data analysis for informed decision-making.

- Access real-time production metrics, performance indicators, and quality data.

- Harness the power of data-driven insights to drive continuous improvement.

3. Elimination of Siloed Data

- Say goodbye to scattered and siloed data across various systems.

- Centralize all relevant data and insights in a single, integrated platform.

- Enable seamless collaboration and information sharing across teams

4. Improved Collaboration

- Enhance communication and coordination among team members for better productivity.

- Break down information barriers and foster a culture of collaboration.

- Empower your team with the tools they need to work together seamlessly.

By harnessing the power of our smart MES for production management, you can optimize your production processes, drive efficiency, and achieve exceptional results. From real-time monitoring to work order management and maintenance planning, our comprehensive suite of tools equips you with everything you need to streamline operations, boost productivity, and stay ahead in the competitive manufacturing landscape.

Stay tuned for the next part of this blog, where we'll explore how our smart manufacturing solution can redefine operations workflows and provide you with the tools you need to excel on the shop floor.

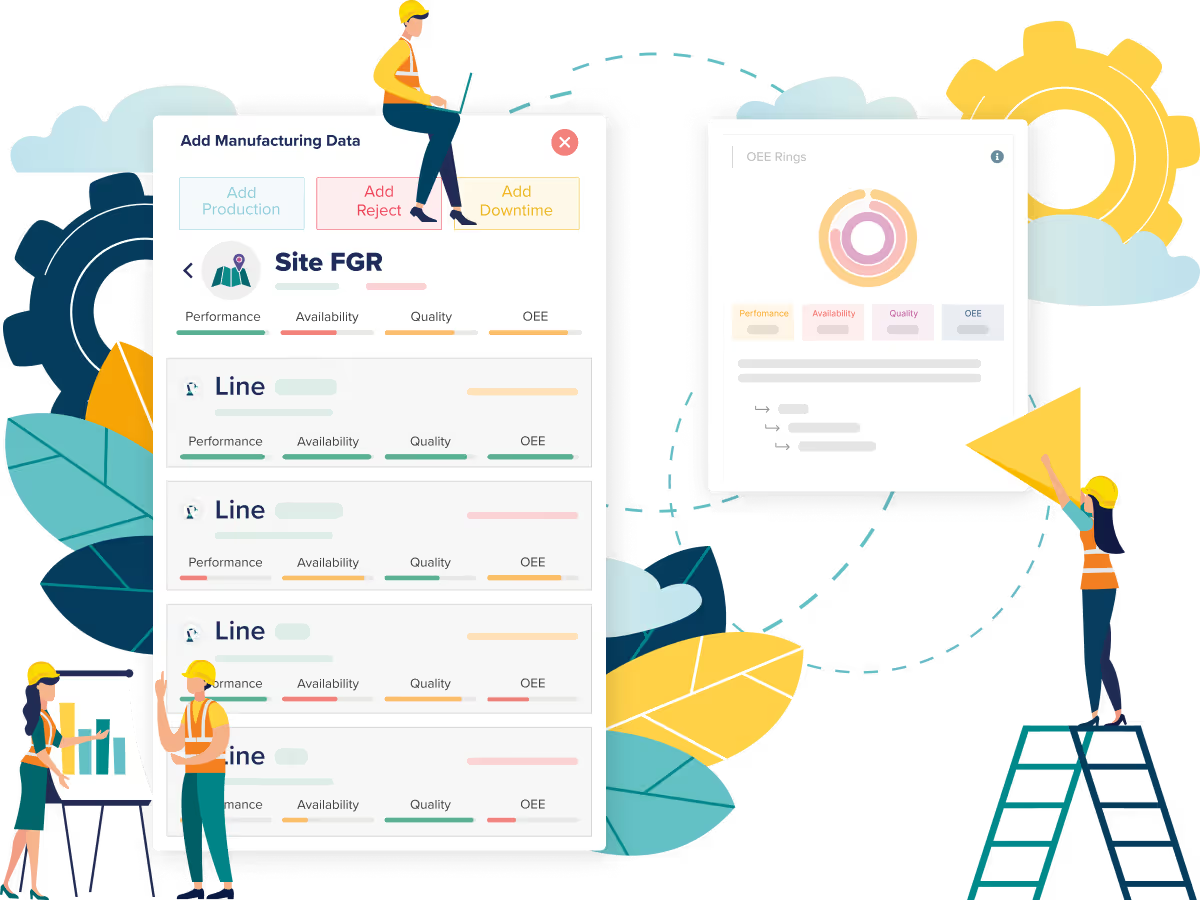

Create Production Workflows with Smart Manufacturing Solution

Efficient production workflows are the backbone of successful manufacturing operations. With our smart manufacturing solution, you can create a highly optimized and synchronized production environment that maximizes productivity and minimizes downtime. Let's explore the key features that make our solution a game-changer for redefining operations workflows.

1. Smart Jobs Scheduling Solution

Streamline your production scheduling and maximize resource utilization with our smart jobs scheduling solution. From work order management to real-time production monitoring, this feature helps you achieve efficient production planning and execution.

2. Work Order Management

Seamlessly manage and track work orders, ensuring smooth execution and timely delivery.

3. Production Capacity Planning

Optimize production capacity by analyzing real-time feedback on production progress, material availability, and line efficiency.

4. Real-time Production Monitoring

Gain valuable insights into manufacturing productivity with real-time manufacturing data and visual dashboards.

5. Remote Multi-Site Management

Access real-time data for all manufacturing sites remotely, enabling efficient oversight and coordination.

6. Centralize Line Production Boards

Streamline shop floor operations with a comprehensive dashboard that displays real-time data from all production lines, promoting visibility and facilitating decision-making.

7. Centralize Site Level Production Board

Monitor all production machines across the site with a centralized dashboard, enabling you to identify issues and implement solutions for underperforming lines.

By leveraging our smart jobs scheduling solution, you can optimize resource allocation, improve production planning, and ensure efficient execution on the shop floor. With real-time insights and centralized visibility, you'll have the power to make data-driven decisions that drive productivity and enhance operational efficiency.

Optimizing Maintenance Planning: Streamlining Operations with Advanced Maintenance Solutions.

Maintenance Planning Solution

Keep your equipment running smoothly, minimize downtime, and enhance maintenance planning with our comprehensive maintenance solution. From predictive maintenance to automated downtime reports, this feature empowers you to proactively manage maintenance tasks.

1. Predictive Maintenance

Import work orders from your ERP system or create them directly in our advanced factory software, enabling you to schedule maintenance tasks proactively.

2. MTBF/MTBR Analysis

Improve Mean Time Between Failures (MTBF) and Mean Time Between Repairs (MTBR) by analyzing real-time production insights and identifying areas for improvement. Read more about these reports here.

3. Asset Maintenance Planner

Schedule and automate recurring maintenance tasks for assets, while analyzing failure rates for each production line, site, or SKU variant to enhance overall equipment effectiveness (OEE) and reduce downtime.

4. Automated Downtime Reports

Analyze the impact of planned and unplanned downtime on production lines, enabling you to optimize productivity and take proactive measures.

5. Line Downtime Trend Tracking

Leverage machine learning (ML) capabilities to gain insights into downtime patterns and reduce production disruptions.

6. Maintenance Planning Tasks

Create and assign maintenance tasks, keeping the entire team informed of progress and completion for streamlined operations.

By integrating our maintenance planning solution into your operations, you can ensure optimal equipment performance, reduce unexpected breakdowns, and optimize maintenance resource allocation. Proactively managing maintenance tasks enables you to minimize downtime, increase productivity, and drive operational efficiency.

Maximizing Performance: Real-time Production and OEE Monitoring for Enhanced Efficiency.

Production and OEE Monitoring

Gain real-time insights into production performance and Overall Equipment Effectiveness (OEE) to optimize efficiency and quality. Our production and OEE monitoring solution empowers you to track key metrics and make data-driven decisions for continuous improvement.

1. Real-time OEE Monitoring

Track the performance of all production machines in real-time, measuring availability, performance, and quality metrics to assess overall equipment effectiveness.

2. Performance Failures Analysis

Identify the main reasons for manufacturing performance failures attributed to the workforce and shopfloor operators. Address these issues to enhance productivity and optimize resource allocation.

3. Availability Failures Analysis

Monitor critical failure reasons for production lines, machines, and equipment to prevent downtime and improve overall availability and uptime.

4. Quality Failures Analysis

Analyze quality failures for each production line or SKU to identify the best and worst performers for specific tasks. Minimize waste and enhance product quality.

5. Monthly Production Boards

Visualize your monthly production schedule on a calendar-style board, providing a comprehensive overview of production key performance indicators (KPIs). Identify trends and opportunities for optimization. See how monthly production boards help manufacturing managers.

6. Real-time Production Rate

Stay informed about the current production rate for each line, enabling you to make timely decisions and adjustments to optimize manufacturing efficiency.With our production and OEE monitoring solution, you can proactively identify areas for improvement, minimize production failures, and optimize overall equipment effectiveness. Real-time insights and performance analysis empower you to make data-driven decisions that drive continuous improvement and enhance your manufacturing operations.

Insights at Your Fingertips: Unleashing the Power of Reporting & Analytics for Informed Decision Making.

Reporting & Analytics Solution

Unlock the power of data analytics and gain actionable insights into your manufacturing performance. Our reporting and analytics solution provides comprehensive reports and analytics to support strategic decision-making and process optimization.

1. Big Data Analytics in Manufacturing

Harness the power of machine learning (ML) and artificial intelligence (AI) algorithms to analyze your manufacturing data, uncover patterns, and gain valuable insights into overall performance and areas for improvement.

2. Production Trends Analysis

Analyze failure rates, production rates, and hourly trends to identify patterns and potential optimization opportunities. Make data-driven decisions to improve efficiency and productivity.

3. SKU Failure Analysis

Improve product quality and performance by conducting SKU-specific failure analysis. Leverage intelligent shopfloor reports to identify issues and implement targeted improvements.

4. Monthly Manufacturing Reports

Streamline your reporting process with automated monthly reports that provide a comprehensive overview of your manufacturing performance. Analyze KPIs, identify trends, and make data-driven decisions for process optimization.

5. Quarterly Manufacturing Reports

Automate report generation for higher-level management. Collect data once and generate all necessary reports automatically, eliminating the need for manual compilation and ensuring accurate, up-to-date information.

6. Annual Manufacturing Reports

Receive yearly reports that summarize your manufacturing performance, highlighting key metrics and insights. Let our professional printing press handle the report generation, saving you time and effort.

Seamless Production Planning: Empowering Manufacturers with Essential Digital Tools.

Get the Digital Tools for Seamless Production Planning

Manufacturing managers often face challenges in effectively managing their team's performance and analyzing the production process without the support of digital solutions. Discover how our digital manufacturing software empowers managers with the tools they need for seamless production planning and improved decision-making.

Smart Software in Production Processes

From identifying bottlenecks to tracking progress and managing resources, smart software plays a crucial role in streamlining production processes and enabling managers to make informed decisions.

In today's fast-paced manufacturing environment, staying on top of production operations and optimizing resource allocation can be a daunting task. Manual processes and disparate systems often lead to information gaps and inefficiencies. However, with the right digital tools in place, manufacturing managers can overcome these challenges and achieve seamless production planning.

Direct Insight into Production Processes

Managing a manufacturing operation involves overseeing various aspects, including production status, resource allocation, and process optimization. Our digital manufacturing software provides managers with direct insight into production processes, enabling them to identify bottlenecks, track progress, and make informed decisions. With real-time visibility into key metrics, managers can proactively address issues and ensure smooth operations.

Improve Production Team Management

Effective coordination and management of the production team are essential for achieving optimal results. Our software facilitates better production team management by enabling streamlined communication, task assignment, and progress tracking. With improved collaboration and accountability, managers can enhance team performance and productivity.

Break Siloed Data with Smart Insights

In traditional manufacturing setups, data is often siloed across different systems and departments, making it challenging to gain a comprehensive view of operations. Our digital manufacturing software breaks down these data silos and provides smart insights that consolidate information from various sources. By bringing together data from production, inventory, quality control, and other areas, managers can make data-driven decisions faster and more effectively.

With smart insights, managers can analyze performance trends, identify areas for improvement, and optimize resources for better production outcomes. By leveraging data-driven decision-making, manufacturing managers can enhance efficiency, reduce costs, and drive continuous improvement.

Production Workflow Management for Shopfloor

Scheduling Software for Manufacturing

Agile Manufacturing Software Solution for Industry 4.0

Shoplfoor Intelligence for Modern Production Practices

Smart Software Attracts Younger Workforce in Manufacturing

As the manufacturing industry evolves, attracting and retaining a younger workforce becomes crucial. Discover how our smart factory software appeals to tech-savvy minds, offering a modern and engaging work environment.

Automated Insights without the Paperwork

Traditional manufacturing processes often involve extensive paperwork and manual data entry, which can be tedious and time-consuming. Our software automates these processes, freeing up time for the workforce to focus on critical tasks and improving overall productivity.

Gone are the days of clipboards and paper-based processes. With our smart factory software, you can create a digitalized work environment that aligns with the expectations of the younger workforce. By replacing manual processes with smart apps and automation, you can enhance engagement and productivity among your workforce.

Increased Production Visibility

Our software provides real-time insights and transparent visualization of production processes. By eliminating delays, errors, and inefficiencies associated with manual data entry, your workforce gains access to accurate and up-to-date information. With increased visibility, employees can make informed decisions and take immediate action, contributing to improved production outcomes.

Improved Team Communication

Effective communication is crucial for a smooth and efficient manufacturing operation. Our software streamlines team communication by reducing the likelihood of miscommunication and errors. With digital tools and centralized information, your workforce can collaborate seamlessly, share important updates, and ensure everyone is on the same page.

Better Data Analysis

Data analysis plays a vital role in driving process improvements and optimizing manufacturing operations. Our software enables comprehensive data analysis, allowing you to identify patterns, trends, and opportunities for optimization. By leveraging key metrics and insights, you can make data-driven decisions and take corrective action when needed.

By providing a modern work environment that leverages smart technology, you can attract and retain top talent in the manufacturing industry. Empower your workforce with the tools they need to succeed and create a culture of innovation and continuous improvement.

Embracing digital manufacturing software is crucial for manufacturing

Embracing digital manufacturing software is crucial for manufacturing managers who strive for operational excellence. By leveraging the power of technology, managers can overcome traditional limitations, optimize production processes, and drive continuous improvement. Our software offers a comprehensive range of features, from production planning and maintenance management to real-time monitoring and advanced analytics. With these tools at your disposal, you can take your manufacturing operations to new heights and stay ahead of the competition.Unlock the potential of your manufacturing operations today with our digital manufacturing software. Contact IfElseCloud to learn more about how our solution can transform your processes and empower your management team to achieve manufacturing excellence.