Smart Data Analytics for Industry Leaders

Embrace the pinnacle of smart manufacturing, where our cutting-edge Manufacturing Execution System (MES) solution turns top leadership's visions into tangible, data-driven reality. Achieve an interconnected future by streamlining processes and automating Shopfloor reporting, all while gaining valuable insights from real-time data.

Start Sustainable Manufacturing Practices

- Take an early-mover advantage toward the Green Manufacturing Future.

- Implement eco-efficient practices and reduce your carbon footprint.

- Embrace circular economy principles and minimize waste.

Implement Industry 4.0 Standards

- Improve data visibility with Machine Learning and AI.

- Connect machines for real-time production insights.

- Foster modern team collaboration for seamless workflow.

Accelerate Digital Transformation

- Eliminate manual data entry and paperwork.

- Improve data visibility across the manufacturing process.

- Embrace automation for enhanced efficiency.

Driving Industrial Transformation: Essential Software Tools for Accelerated Innovation and Efficiency.

Software Tools for Industrial Transformation (IX)

Navigate the digital transformation with confidence, guided by AI-driven insights and seamless interconnectivity. Experience the ultimate convergence of technology and human touch, addressing pain points for a truly modernized Shopfloor environment.

Advanced Shopfloor Automation

Automate data acquisition and gain real-time insights with connected devices. Bridge the gap between cyber-physical systems and enhance data-driven automation.

Data-Driven Decision Making

Leverage AI and Machine Learning to analyze vast amounts of data for informed decision-making. Identify patterns, trends, and anomalies to optimize production processes.

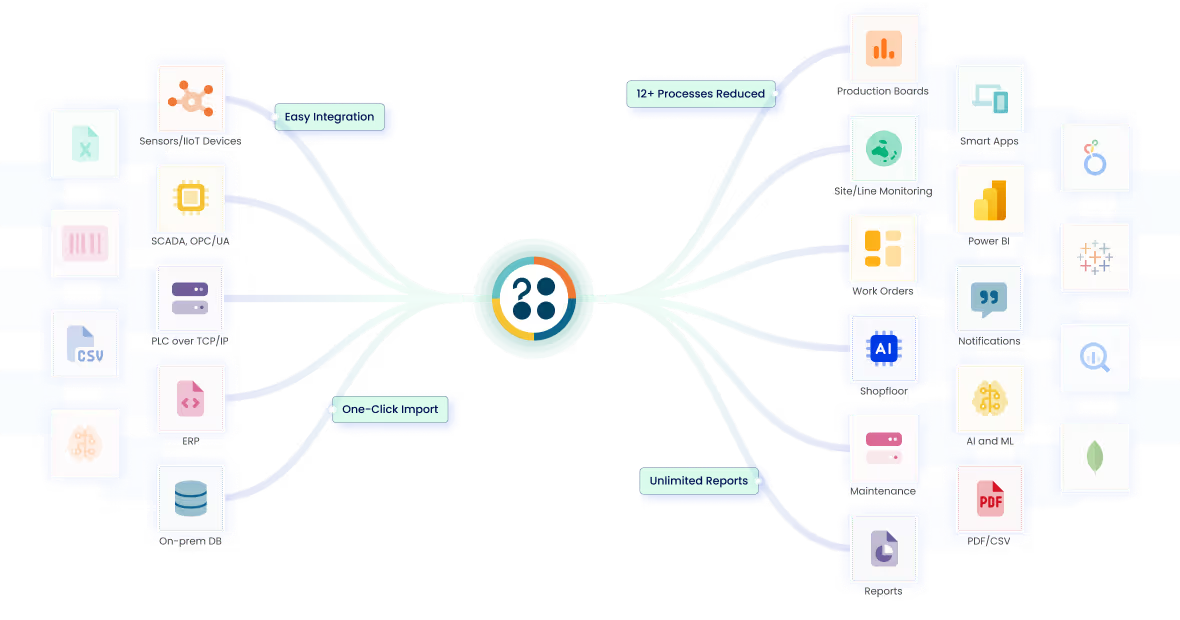

Seamless Integration

Integrate our software seamlessly with existing systems, such as IIoT, SCADA, OPCUA, and ERP. Achieve a unified digital ecosystem that enables efficient data exchange and collaboration.

Agile Manufacturing Practices

Embrace agile methodologies to enhance flexibility, responsiveness, and adaptability. Optimize production processes, reduce job backlogs, and meet customer demands with greater agility.

Lean Manufacturing Implementation

Implement lean manufacturing practices for waste reduction, process optimization, and continuous improvement. Identify areas for improvement, streamline workflows, and optimize resource allocation.

Embrace Digitalization: Leading Your Enterprise Towards a Future of Innovation and Growth.

Lead Your Enterprise Towards Digitalization

Get rid of papers and whiteboards - let your team enjoy the modern digital experience they crave, and secure your place as an industry innovator, attracting fresh and younger talent.

Paperless Operations

Replace traditional paper-based processes with a digital manufacturing platform.Streamline workflows, eliminate manual errors, and enhance efficiency.

Real-time Collaboration

Bring all teams on the same page with digital dashboards and real-time communication tools. Enhance collaboration, transparency, and knowledge sharing across the organization.

Attract Younger Workforce

Create a digital factory environment that appeals to the younger generation. Leverage modern technologies and practices to attract and retain top talent.

Industry Innovation

Embrace digitalization to position your enterprise as an industry innovator.Stay ahead of competitors by leveraging cutting-edge technology and practices.

Leading the Charge in Industry 4.0: Embrace the Digital Revolution and Drive Transformation.

It's the Era of Industry 4.0 and You Are the Leader

As a forward-thinking leader, you know it's key to use technologies like AI and Machine Learning to stay ahead in the game. Our Smart Factory Software packs in many tools like Manufacturing Execution Systems (MES), Shopfloor Intelligence, Lean Manufacturing practices, and predictive planning. With Our Digital Factory Software, your manufacturing always has a modern software layer.

Gain complete control and visibility over your manufacturing operations.Track and manage production orders, inventory, and quality control.

Shopfloor Intelligence

Access real-time insights and analytics to optimize production performance.Monitor Key Performance Indicators (KPIs), detect anomalies, and take proactive actions.

Lean Manufacturing Practices

Implement lean principles to eliminate waste, increase efficiency, and improve overall quality. Streamline processes, reduce lead times, and enhance customer satisfaction.

Predictive Planning

Utilize predictive analytics and machine learning algorithms for demand forecasting. Optimize production planning, minimize inventory holding costs, and reduce production downtime.

Critical Insights for Top Leadership: Gaining the Edge in Decision-Making and Strategic Planning.

Insights That Top Leadership Needs

In today's highly competitive manufacturing landscape, effective leadership requires access to timely and relevant insights. With our Advanced Factory Software, you can gain the valuable data and analytics needed to make informed decisions, drive growth, and enhance profitability.

Our interconnected production sites feature allows you to remotely monitor manufacturing processes across multiple locations, providing real-time visibility into performance metrics and production data. Additionally, our annual production board feature enables you to generate comprehensive reports for the entire year in less than a minute, empowering you to plan production efficiency and make data-driven decisions.

With executive reports, you can identify areas for cost reduction, optimize resource utilization, and increase profitability. Our white-labeled platform allows for customization, tailoring reports and analysis to suit your specific requirements.

Improve your smart industry readiness and achieve automation, connectivity, and intelligence with IfElseCloud's Smart Factory Software.

Use Big Data Analytics for a Smarter Future of Your Enterprise

The manufacturing industry is undergoing a transformation fueled by advancements in data analytics. Leaders need to leverage big data to drive growth, manage risks, and stay ahead of the competition.

With our digital MES solution, you can collaborate with digital dashboards and access real-time insights to make strategic decisions based on accurate and up-to-date information. Innovate with a younger workforce by offering a digital factory environment that attracts top talent and retains customers through future-proof manufacturing practices.

Furthermore, by using predictive analysis, you can manage risk proactively, reducing financial losses and meeting customer expectations. Embracing big data analytics positions your enterprise for success in a rapidly evolving industry.

Redefine Innovation with the Unified Digital Manufacturing Platform

Innovation is crucial for manufacturing leaders striving to achieve sustainable growth and maintain a competitive edge. Our unified digital manufacturing platform empowers leaders to redefine innovation within their organizations.

By utilizing executive reports, you can gain deeper insights into operations and critical data points, facilitating strategic decision-making that drives growth, profitability, and innovation. Effective risk management is essential, and our platform enables you to identify and mitigate risks related to production processes, supply chains, and other key areas, safeguarding your business from financial losses.

By leveraging the platform's capabilities, you can maintain a competitive advantage by staying ahead of the competition, innovating more effectively, and quickly adapting to changing customer needs. Embrace the power of the unified digital manufacturing platform to unlock new levels of innovation and drive your enterprise toward a successful future.

Production Scheduling Software for Manufacturing

Take the next step to digitalize your site!

Unified Digital Manufacturing Hub for Modern Industry Teams

Access centralized reports with ML & AI

Embrace Smart Data Analytics and Digital Transformation

In today's rapidly evolving manufacturing landscape, staying ahead of the competition requires embracing smart data analytics and digital transformation. By implementing an advanced Manufacturing Execution System (MES) and leveraging the power of AI, Machine Learning, and IoT, leaders in the manufacturing industry can unlock new levels of efficiency, productivity, and profitability.

Don't let your factory be left behind. Contact IfElseCloud today to revolutionize your manufacturing operations, optimize performance, and position yourself as an industry innovator. Our team of experts is ready to guide you through the digital transformation journey and help you achieve greater efficiency, profitability, and competitiveness in the market.